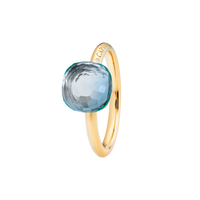

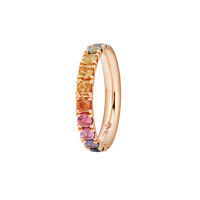

Colorful

Colored stones – how nature created them

CAPOLAVORO also focuses on nature when selecting colored stones and only uses natural stones that are sourced and cut in the German gemstone metropolis of Idar Oberstein. This is an absolute sign of the best quality, because only with the perfect cut can a stone develop its own personality. Because every colored stone is a little different, the topazes, sapphires, amethysts, morganites and other beauties from our collections can vary slightly in their nuances.

Behind the Scenes

Gemstone cutting

The art of gemstone cutting combines centuries-old craftsmanship with the latest technology to bring out the natural beauty, brilliance and color of gemstones.

Colorful

A natural wonder

The formation of all colored stone minerals, of every single crystal, is always a miracle of nature and tells of its history long before our time.

Awakening the color intensity

The First Cut

Depending on the type of stone, the stone cutter selects precise axes and makes the first cut with a diamond saw to achieve the best possible color intensity for the final result.

The gemstone designer then shapes the stone with loving attention to detail in the first phase of ebouching. In the subsequent steps, the basic structure created by ebouching is further refined with great care and precision.

A central element

The putty stick

Putty sticks play a central role in the art of gemstone cutting. The individual stones are securely fixed on these special holders. By attaching the stone to the putty stick, the stone is positioned optimally, which enables more precise and efficient processing in the following steps. It also makes handling easier and enables a thorough inspection of the stone from different angles. Thanks to the careful construction of the putty stick, the stone can be removed easily and without leaving any residue after the work is completed.

the perfect

Faceted cut

The fine facets of the stone are carefully and masterfully ground from different sides on the diamond grinding stone. This process requires not only skill, but also a deep understanding of the individual properties of each stone in order to bring out its natural beauty to its full potential. After grinding, the facets are polished with great precision and care to flawless perfection. A trained eye is crucial to ensure that no streaks are created during this process and that the gemstone can unfold its full shine. The ability to recognize and work on the finest details is essential to allow the gemstone to shine in its full glory.

Technically supported

Precision grinding

In modern gemstone cutting, especially in the manufacture of series products where the highest precision and exact calibration of the colored stones are required, a technology-based method is used: quadrant cutting. By combining traditional craftsmanship with the latest technology, an optimal result is achieved that meets the highest quality standards and at the same time enables efficient and precise production.

Our Dear

Gemstone cutting Comapny HC Arnoldi

As a traditional gemstone cutting and gemstone trading company from Kirschweiler near Idar-Oberstein, HC Arnoldi has been serving the global jewelry industry, like CAPOLAVORO, with a wide variety of colored gemstones for more than 100 years.

A big thank you goes to the Arnoldi family for the enchanting glimpse behind the scenes. >> Find out more.

Learn more

Gemstone lexicon

In our gemstone lexicon, you will find exciting know-how about the sparkling masterpieces from our earth.